How does laser cutting of plastics with a laser work?

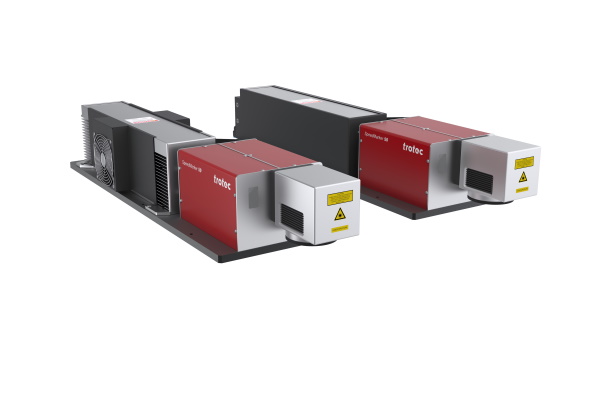

Cutting acrylic is one of the most common laser applications. But other plastics, such as polycarbonate, polypropylene and polyethylene, can also be cut with the laser. Typically, CO2 lasers are used for this type of laser cutting. This wavelength reacts very well with a large number of plastic materials.

What are the benefits of using laser machines for cutting and engraving plastics?

Depending on the type of plastic, laser cutting, laser engraving and laser etching offer a number of benefits: When laser cutting acrylic, for instance, the user will be impressed by the flame-polished cutting edge produced. When working with polycarbonate films, the laser can score thanks to a smoke-residue free cut and its high processing speed. Laser cutting polyester will produce a cleanly sealed cutting edge.

How does laser marking and engraving of plastics with the laser work?

Many commercially used plastics can be marked and engraved durably, forgery-proof and in high quality with the laser. High flexibility and short setup times allow for economical marking even of small batch sizes. Typically, clear texts, datamatrix codes or logos are applied. Fiber lasers are predominantly used for marking and engraving.

The following materials are especially suited for this process: ABS, PA, PI, PES, PC.

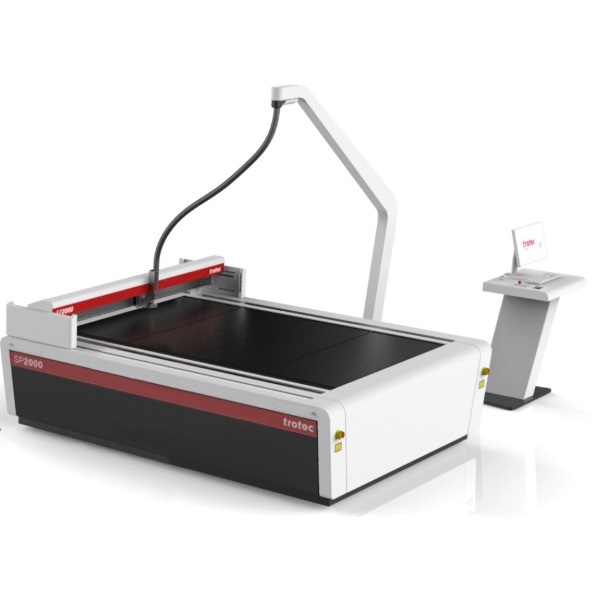

Why do laser machines cut faster than a cutting plotter?

Accurately adjusted axis drives and an innovative control technology guarantee that laser cutting with Trotec systems is fast and accurate. Unlike in cutting plotters, there is no material resistance when using the laser. As a result, working with the laser is faster. Another plus: It is not necessary to lift or turn the laser beam with a knife. Trotec laser systems make full use of this advantage in speed and detail, especially when working with fine geometries.

Do I have to fixate the material on the working surface?

No. The laser does not exert any pressure on the material during the process; clamping or any other type of fixation is not required. Simply insert the workpiece and start the laser process. This saves time and money during preparation of the material.

Plastics that can be cut, marked and engraved with the laser

| Material | Abbreviation | Trade name |

| Polyamide | PA | Nylon® |

| Polyoxymethylene | POM | Delrin® |

| Polyester | PES | Thermolite®, Polarguard® |

| Polyethylene terephthalate | PET | Mylar® |

| Polyimide | PI | Kapton® |

| Polystyrene | PS | |

| Polymethyl-methacrylate | PMMA | Plexiglas® |

| Polycarbonate | PC | Lexan®, Makrolon® |

| Polypropylene | PP | |

| Acrylonitrile butadiene styrene co-polymerisate | ABS |