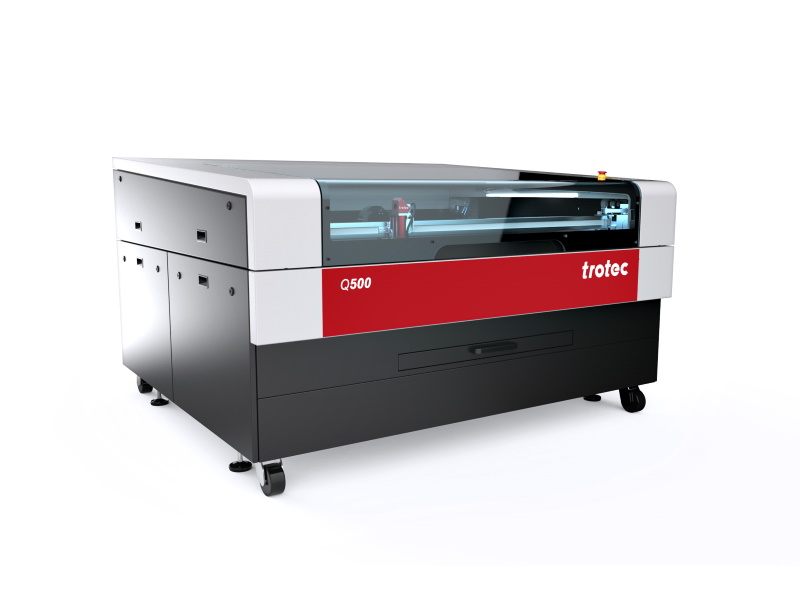

Large-format cutting laser with a working area of 1300 x 900 mm and a 120 W DC RECI tube. A cheaper version of the SP500 machine, but it contains new electronics like the new Speedy 400. It enables precise cutting of materials such as acrylic, wood, textile, paper. In addition, with the RF tube, it can engrave quickly and accurately.

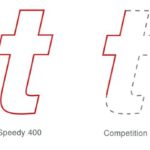

Fastest laser cutting with OptiMotion

Maximum cutting speed with the highest cutting quality – that’s what OptiMotionTM motion control stands for – the innovative Trotec motion planning. Cutting speed and acceleration are automatically calculated and optimized in real time based on the geometry. The result: Saves time when creating laser files and determining parameters, high curve quality and maximum throughput. The Q500 is up to eight times faster when cutting than comparable laser machines on the market.

Maximum productivity

The Q500 is equipped with Trotec core technology that has been tried and tested for decades. These trademarks set standards for your productivity:

The Q500 delivers the finest engravings up to a font size of 4 pt with sharp shoulders and defined details at up to 2m/s. The Trotec drive concept delivers the speed and ensures that it is more than a data sheet value.

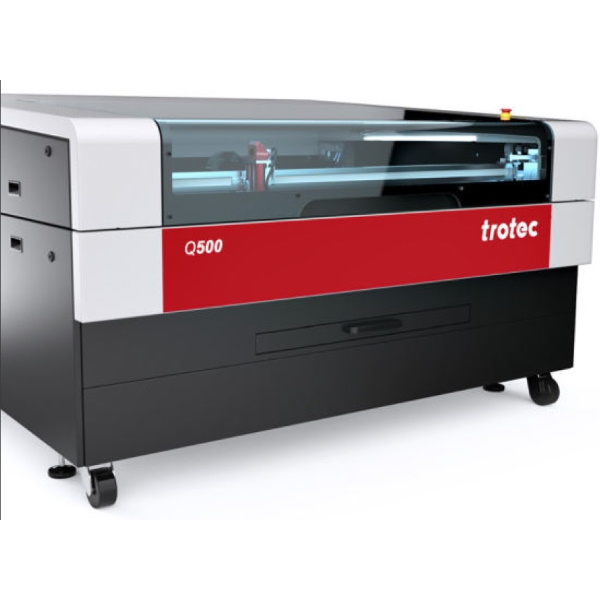

Efficient and intuitive work

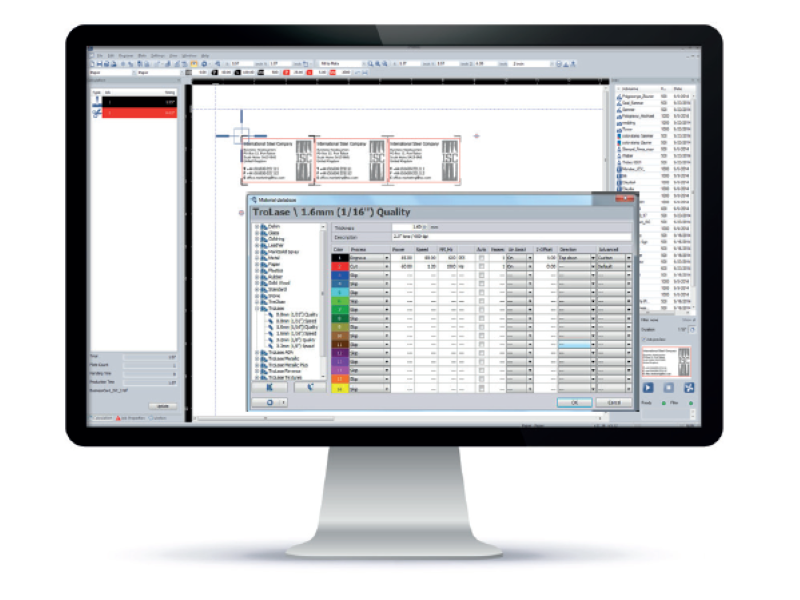

The JobControl® laser software was developed to be easy to use and highly efficient. Whether you are a beginner or an experienced user, Trotec JobControl® facilitates your daily work with the laser and supports you with perfect results. Work in your usual graphics program and simply send your jobs to the laser using a printer driver. As well as being easy to use, JobControl® offers a variety of intelligent options. For example, the JobTime Calculator, bi-directional communication, markers, vector sorting, job preview and a number of others. The JobControl® Vision camera system makes it easy to cut printed materials with a perfect fit.

InPack Technology

Protects all sensitive components of the laser engraving machine such as the lens, mirror or motor from dust. You save time and money.