How does cutting and engraving of acrylic with a laser work?

The laser cut produces crystal-clear cutting edges and inner contours and no additional after-treatment of the material is required. Cast PMMA is cut without burrs. No cost- and time-intensive manual flame polishing of the cutting edge is required. When engraving acrylic glass and Plexiglas, the laser removes the surfaces.

What effect can I achieve on acrylic glass and Plexiglas®?

With the laser, you can realize even the most delicate geometries or photo-engravings on acrylic. The inner edges are crystal-clear and flame-polished, and the laser user generates added value with the new products.

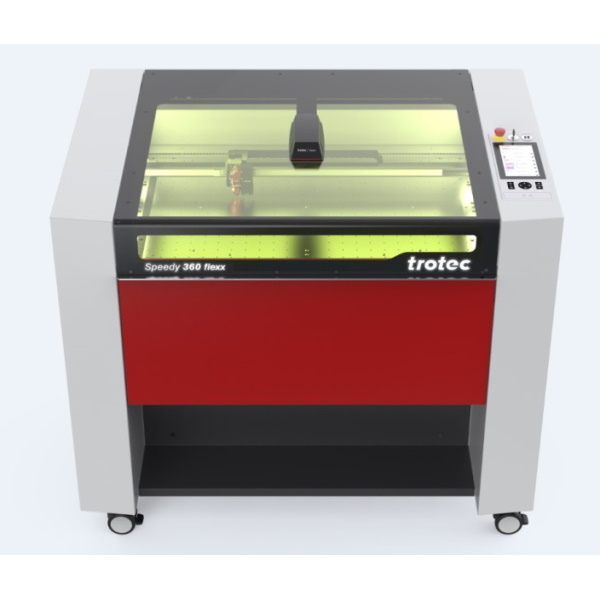

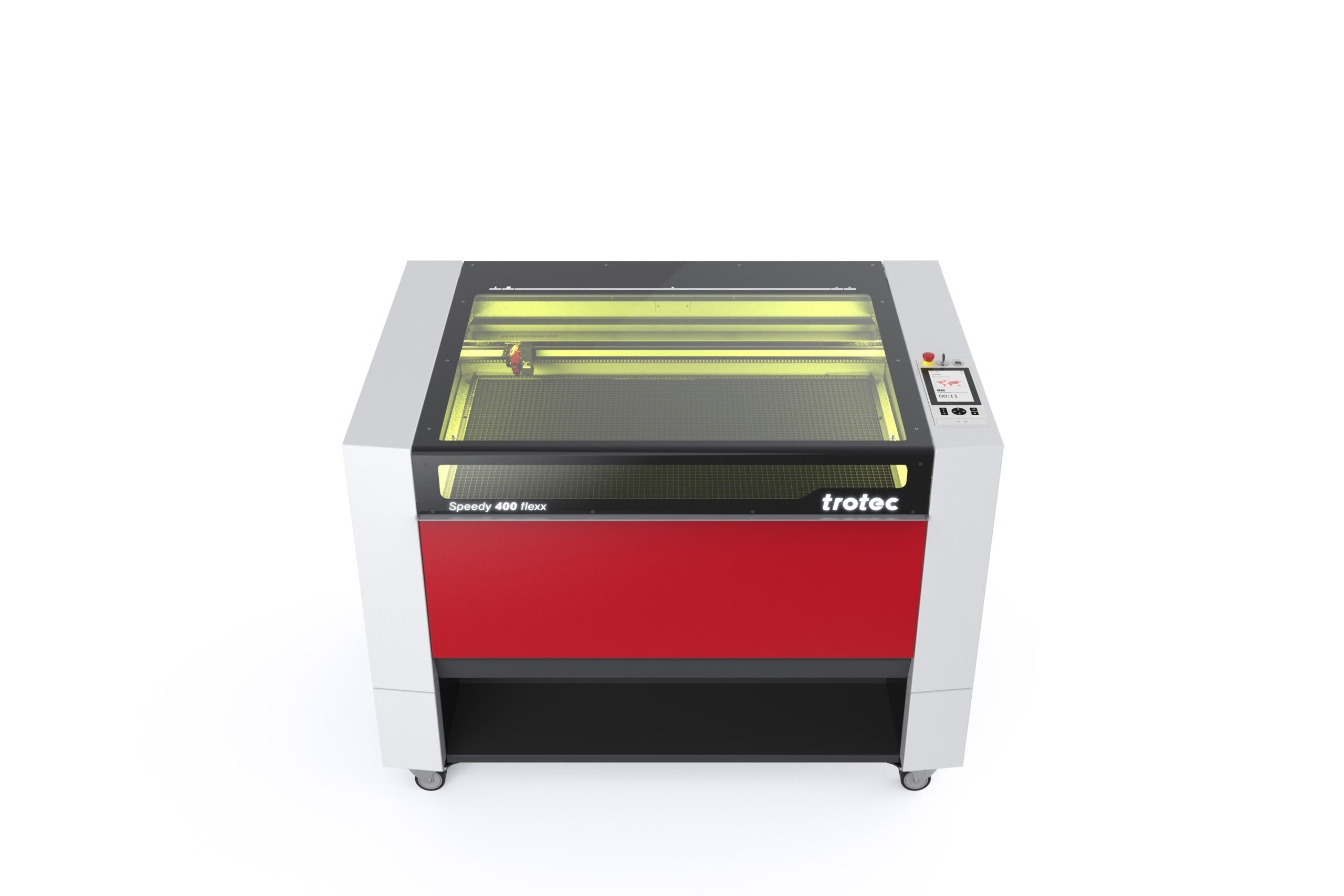

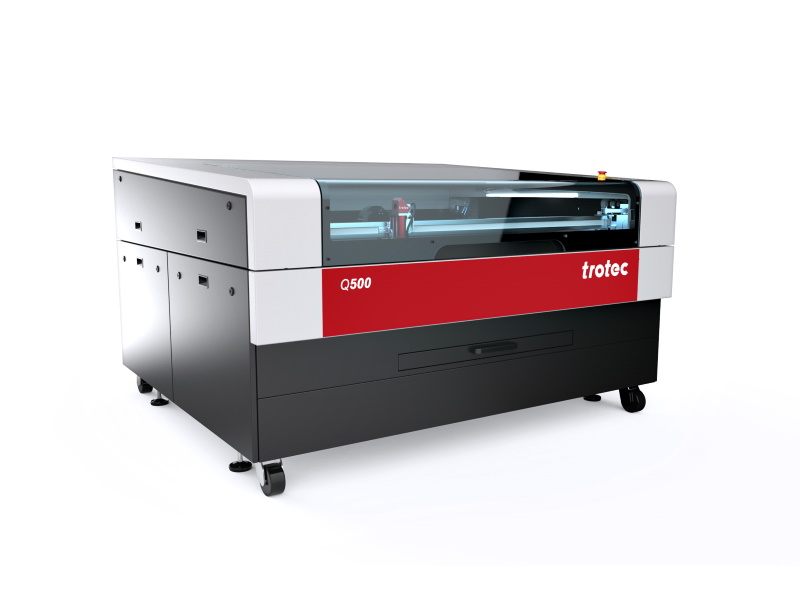

Precise axis drives and intelligent air flow of the Trotec systems ensure always optimal results when laser cutting Acrylglas®. Low-reflection aluminum support lamellas guarantee that workpieces always turn out perfect.

What about the vapors produced during acrylic cutting?

Vapors are extracted and filtered directly in the engraving compartment. This saves time during cleaning of the system. Unlike milling cutters, no chips, which need to be disposed of at high cost afterwards, are produced during laser cutting of plexiglass.

Do I have to fixate the material on the working surface?

No. The laser does not exert any pressure on the material during the process, clamping or any other type of fixation is therefore not required. Simply insert the workpiece and start the laser process. This saves time and money during the preparation of the material. When acrylic is cut by milling, on the other hand, the plate material must be clamped in place and often be fixated with a vacuum.