How does laser cutting and engraving of textiles work?

Laser engraving refines the surface of the material, thus increasing the quality of the fabric. Unlike in printing, laser engraving additionally produces a haptic effect. Particular benefits when working with the laser on textiles are its speed, flexibility and precision. Moreover, the nesting feature included in the laser software ensures economical use of the fabrics.

What designs and formats can I cut with a fabric laser cutter?

Whether engraving fleece or producing extravagant form cuts on curtains or lace – the laser offers the user incredible design options, as virtually any design can be realized with the laser.

What are the advantages compared to conventional cutting processes?

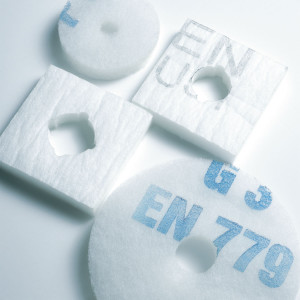

Laser cutting is a contact-less and tool-free process. There is no contact and consequently no warping of textiles and fabrics during laser cutting. The laser beam melts the material and the result are clean, perfectly sealed edges. It is guaranteed that there will be no fraying of the end products.

Can I cut all materials equally well with the laser?

Synthetic materials respond very well to laser cutting. They very often contain plastic or polyester. The laser beam melts the polyester in a controlled manner, which ensures non fraying edges. When cutting organic textiles, such as cotton or linen, with the laser, the produced cutting edge will show some brown discoloration, similarly to wood. To some degree, this effect can be compensated for by selecting the correct lens and laser parameters, and by the use of compressed air.