How does engraving of leather with a laser work?

The laser sublimates the leather surface, which means that the leather changes to its gaseous phase (“evaporates”). With increasing laser performance and decreasing travel speed, the depth of the engraving is increased. Genuine leather but also many imitation leather sorts are suited for processing with a laser.

What are the advantages of a laser machine when working leather?

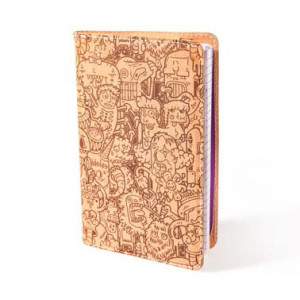

When laser cutting, etching and engraving leather, motifs, letters and designs are burnt into the leather. Another plus of laser cutting leather is the clean and sealed cutting edge it produces. There will be no fraying of the material.

Why is a laser cutter faster than a cutting plotter?

Unlike other methods, working with the laser is contact-less. Leather is tough and produces significant resistance for the tool. The only exception is the laser beam. Another positive side effect: The laser produces constant results, without any wear or tear.

Do I have to fixate the material on the working surface?

No. The laser does not exert any pressure on the material during the process; clamping or any other type of fixation is not required. Simply insert the workpiece and start the laser process. This saves time and money during preparation of the material.