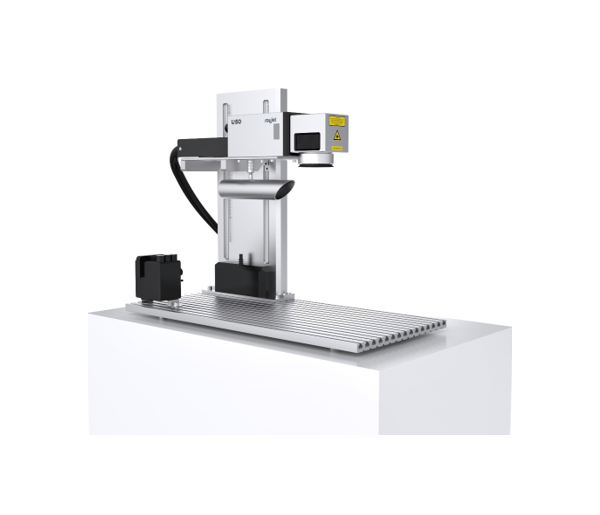

What are the benefits of laser marking on metals?

Marking metals with the laser is an extremely accurate and clean way of working on metal. Markings such as serial numbers, codes and logos can be applied on products and components in maximum resolution. Metal etching and engraving with the laser is contact-less; the metal surface is not damaged.

In what areas is laser marking of metals used?

Typical areas of application for laser marking of metals include product labeling and coding in the electronics industry (mobile phones, iPad – mostly eloxal marking), tool construction, and medical technology. Annealing marking (see below) is an especially suitable process that allows for burr-free marking that is gentle on the material.