Leading Large Format Laser Cutting

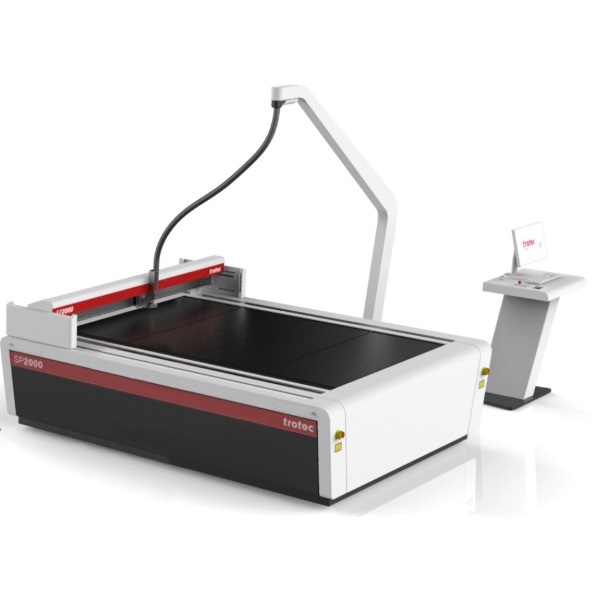

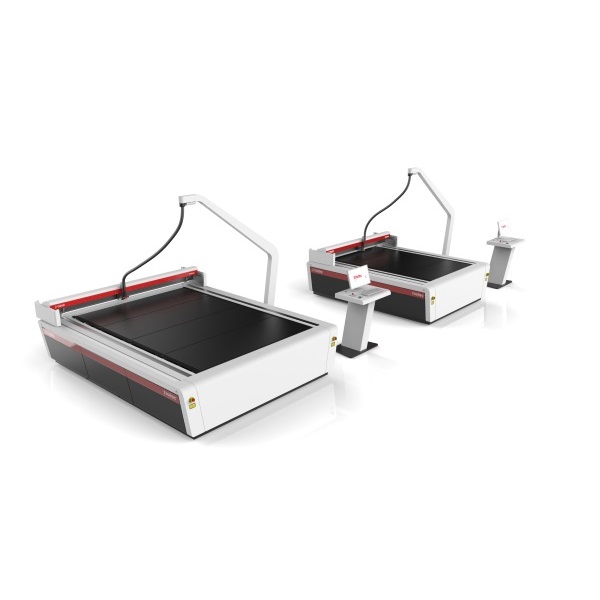

The brand new laser cutter has a working area of 1,65 x 2,51 meters and is perfectly suited for cutting large format materials like acrylics, textiles, cardboard and more. Thanks to an innovative drive technology and its rigid design, the SP2000 is ready for 24/7 production. Fast, productive, reliable.

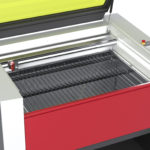

Outstanding Working Area

The working area of 1.650 x 2.510 mm of the SP2000 is designed for large format materials. It is easy to access from all four sides. The loading area is 1.680 wide, open at the front and the rear. The open design allows unloading and loading from all four sides even during processing. This makes your daily work with the SP2000 even more productive.

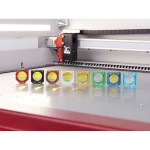

High Speed Cutting at Highest Quality

Even at highest speeds, up to 1 m/ sec and 1g acceleration, the SP2000 delivers cutting quality beyond compare. The innovative drive technology, the precise mechanical guidance system and the superior mechanical concept state the engineering excellence made in Austria.

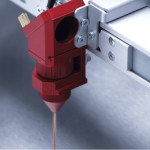

Air-flushed Optics for Excellent Cutting Edges

All optics are air-fl ushed with clean compressed air during laser processing. The optics are kept free from dust that is produced during cutting. This is providing a maintenance-free operation and a long life of the high-quality components.

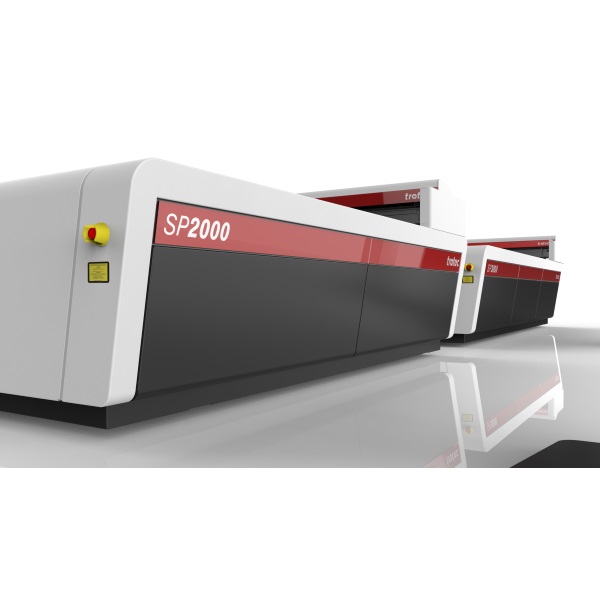

Fully Closed Beam Path for 24/7 Operation

The laser beam is protected over its complete path. Safe operation is guaranteed. The laser class 4 system can be operated as safe as a laser class 2 system in normal operation. No additional safety measures are necessary.