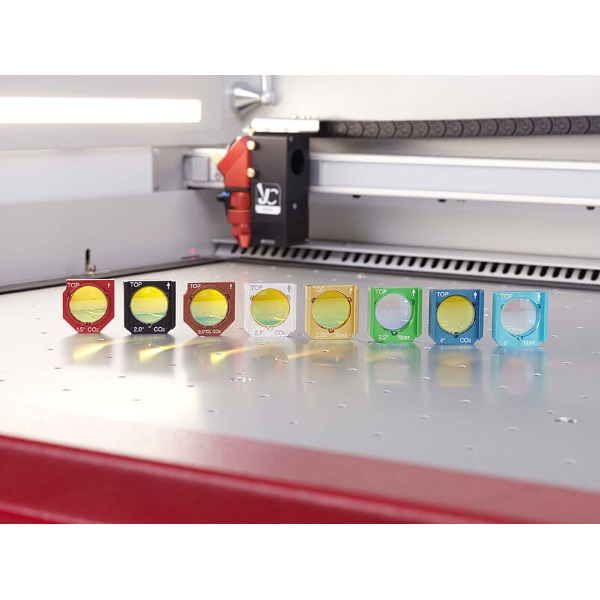

The right lens for perfect results

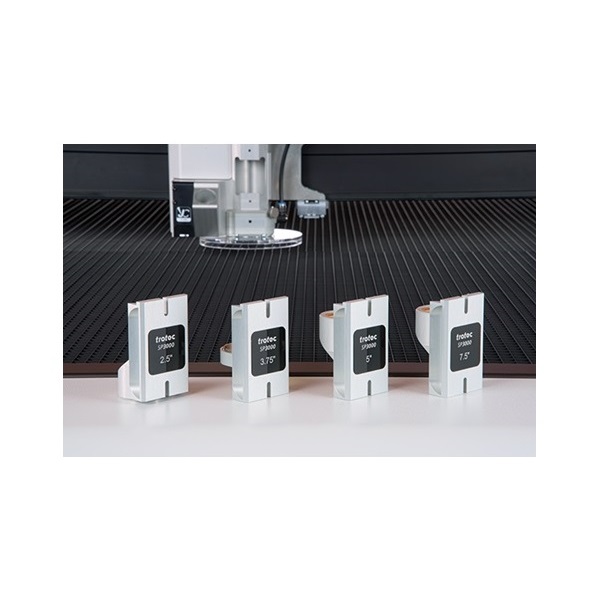

Optimal results during laser engraving or laser cutting are achieved by using different lenses. This works in the same way as for a camera that uses different lenses for close-up and wide angle photographs. The various lenses differ by their respective focal distances. The focal distance is indicated in inches. This is the distance from the lens to the focus. The focus, in turn, is the smallest beam diameter (before and behind the focus, the beam expands again). A small beam diameter means a high energy density (= intensity), i. e. an ‘aggressive’ beam. A focal distance of 2 inches, for example, means that the maximum intensity is reached when the workpiece surface to be cut or engraved is positioned 2 inches (= 5.08 cm) underneath the lens.

How to choose the right focus lens

The decision on what lens to use depends on a number of factors: laser power, type of material, degree of detail and resolution of the graphic (dpi), thickness of the material. The following rule of thumb can be applied: The greater the degree of detail of the graphic, the shorter the focal distance during laser engraving. The thicker the material during laser cutting, the greater the focal distance.

The depth of field (focal tolerance), in turn, specifies the area in that the laser beam is optimally focused. The longer the focal distance, the longer the depth of field. This means that the depth of field of a 5 inch lens will be about twice as long as for a 2.5 inch lens. For this reason, the cutting edge of thicker materials will turn out straighter when a 5 inch lens is used than when a 2.5 inch lens is used.

At the same time, the laser beam diameter will be greater the longer the focal distance is (for a 5.0 inch lens approx. twice as big as for a 2.5 inch lens). As a result, the energy of the laser (wattage) will be distributed onto a larger surface. Consequently, less power (here in the form of heat) per surface area will be applied. The use of a lens with a greater focal distance can therefore be advantageous for materials that react sensitively to heat (e. g. laminates). The greater focal diameter means a greater line width. Filling lines can therefore be cut with the laser at a greater distance and thus faster.