Create Print&Cut acrylics, paper, film or cardboard products.

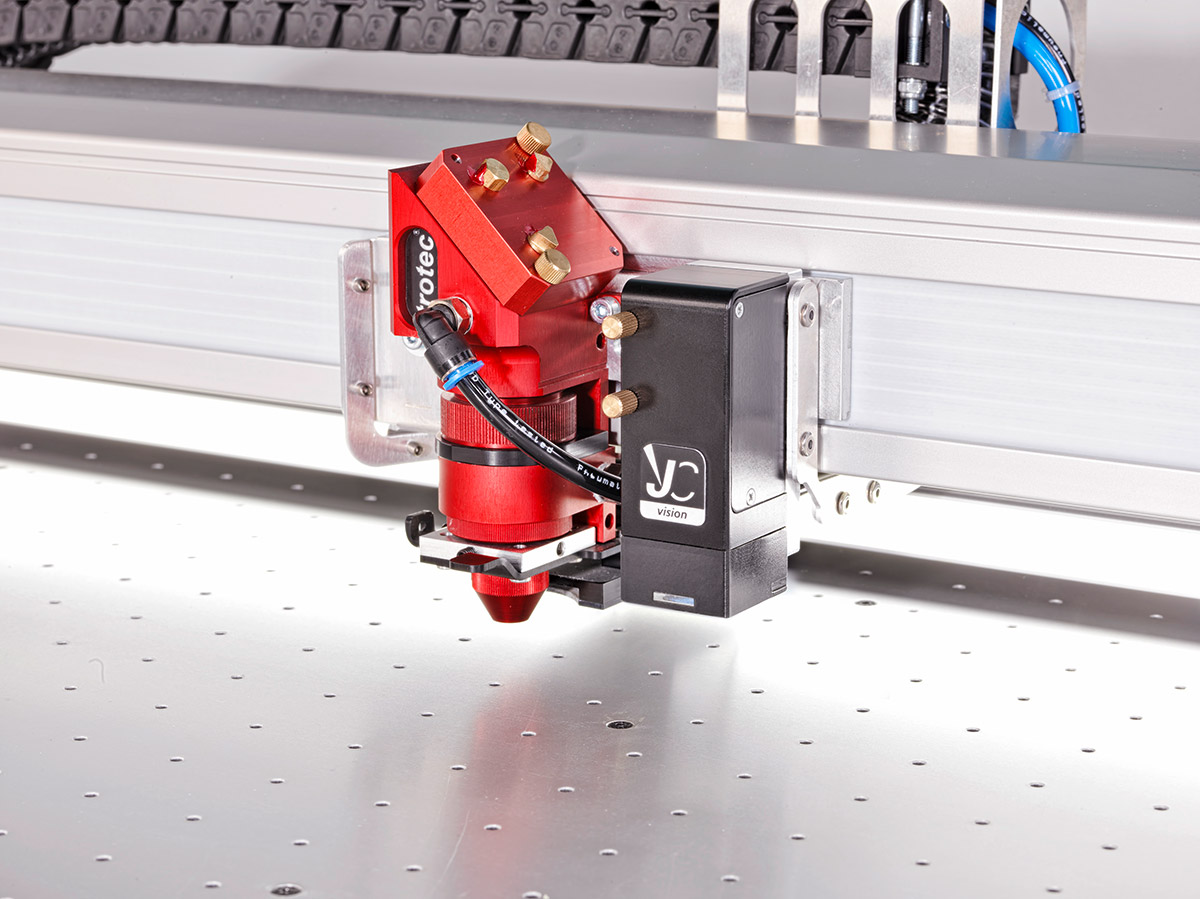

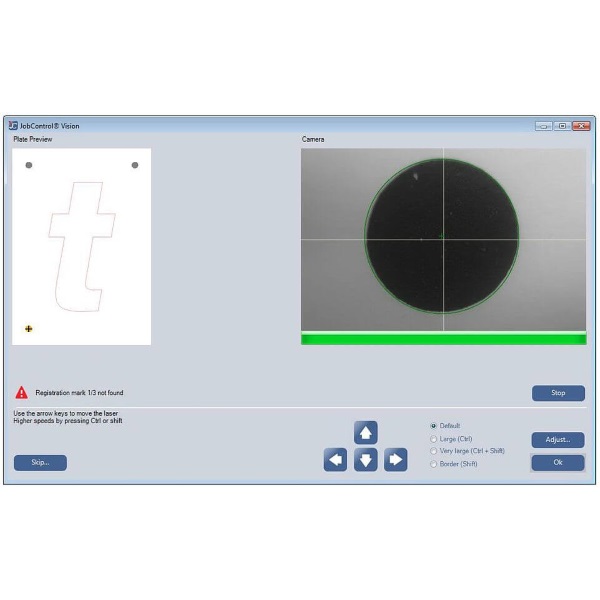

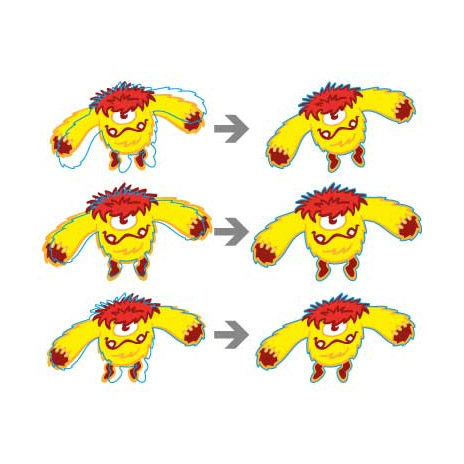

The Vision module uses registration marks to determine the position and rotation of printed sheet material on the working area of the laser. Additionally, any distortions – linear or non-linear – in the printed graphics are recognized with the intelligent JobControl® Vision camera. By applying sophisticated mathematical algorithms the system compensates for the detected print distortions and adjusts the cutting path dynamically to match the artwork. No matter if flexible or rigid materials.

How it works in simple words

The registration marks are printed along the image. The camera – which is attached to the working head – “reads” the registration marks prior to the cutting process and compares the “read” positions on the printed design and the target positions in the original cut file. Any deviations are adjusted automatically. There is no need for manual alignment which speeds up your production and costly miscuts can be avoided. This guarantees a perfectly cut end product.

How to

Create amazing details and meet tightest tolerances with JobControl® Vision.