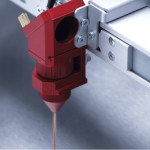

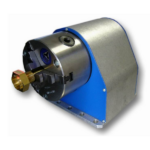

Laser system Megaflex-SHINE CO2 is a compact unit that is suitable for integration into a production line as well as for independent use. Allows permanent marking on different types of surfaces (rubber, glass, plastic, paper, wood, anodized metals …) at high speed. Using peak scanner head Megaflex-SHINE reaches highly accurate marking at high speeds. It is equipped with CO2 laser tube with air or water cooling.

The laser is suitable for marking plastics, anodized aluminum, glass, paper, rubber, etc. Version OEM (Original Equipment Manufacture) is a laser class 4, without protective covers!

The system is controlled by an integrated PC software Megaflex-SCAPS, which represents a powerful vector editor with simple controls, but with maximum flexibility – both vector and bitmap graphics, set parameters of the laser, full support for all fonts (in addition laser fonts), import / export from / to major graphic formats, automatic data, serial numbers, actual date and time, barcodes, 2D codes. Moreover, the possibility of a complete external control via LAN and Internet (TCP / IP) and support for individual customer solutions – programmability and scripting (C ++, Visual Basic).

Megaflex-SHINE is specifically designed for use in industrial environments, resistant to external mechanical influences and dustproof. Using components from leading manufacturers gives the system a long life and trouble-free operation, which requires minimal maintenance.