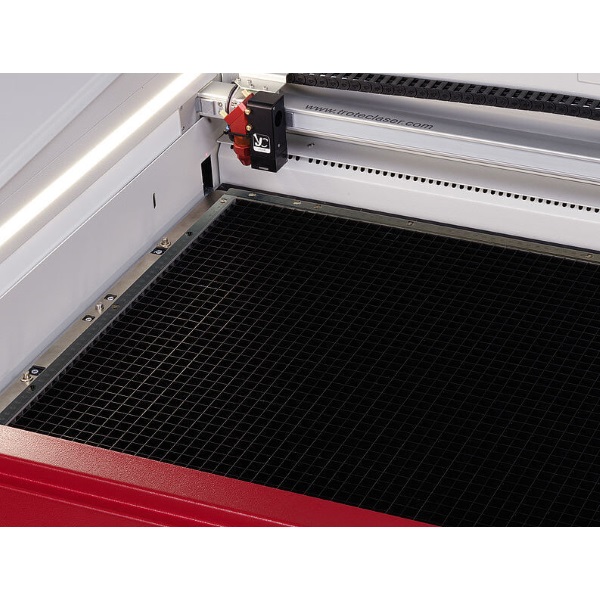

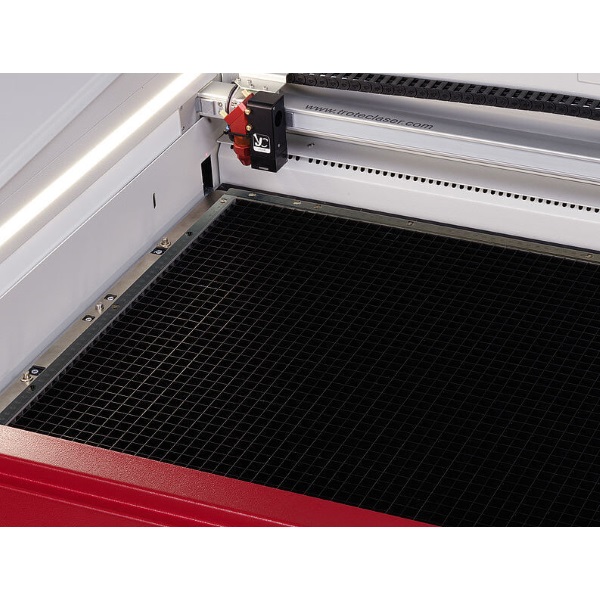

Black aluminium grid table

This robust universal cutting table features extremely stable combs and a long service life. This is particularly suitable for cutting

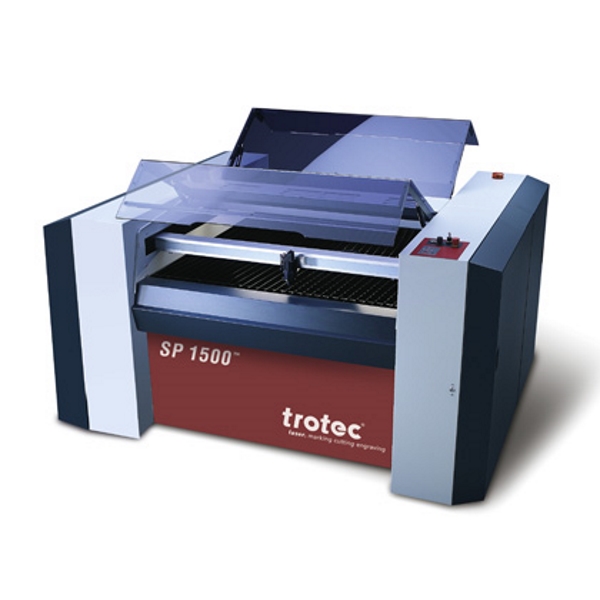

Trotec lasers for marking, engraving and cutting are supplied in such a configuration that they can be used immediately – of course after installation by our technicians and initial training in operation and maintenance. In addition to standard accessories such as a laser pointer, metal table or JobControl software, it is suitable for some applications, to increase productivity or for greater operator comfort, to supplement the laser with optional accessories.

This robust universal cutting table features extremely stable combs and a long service life. This is particularly suitable for cutting

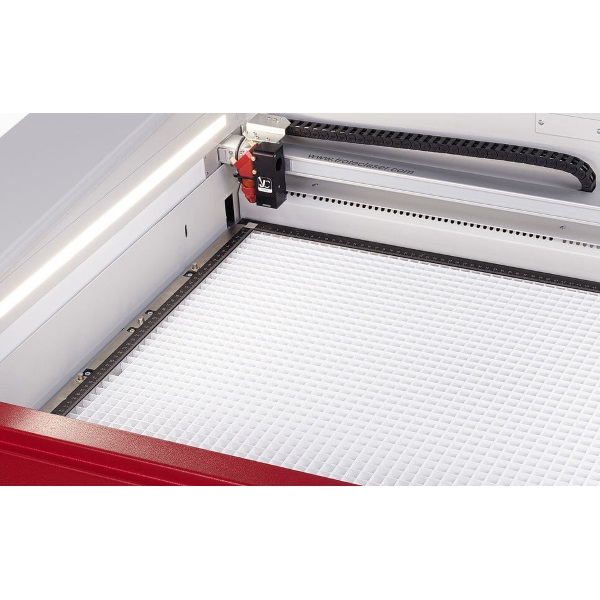

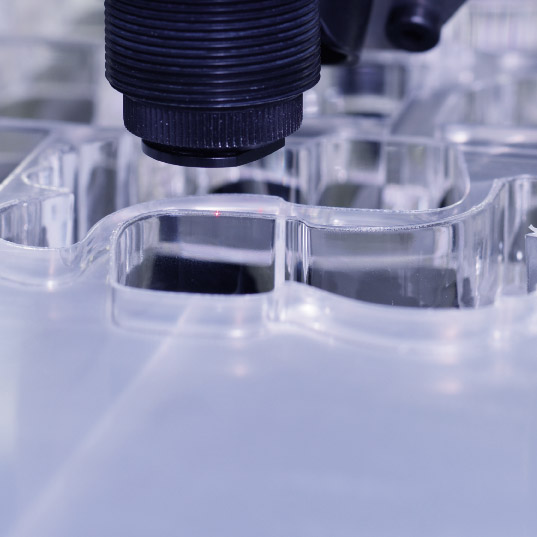

Universal cutting table for thin plexiglass cutting up to 8 mm thickness without reflection. As with the black aluminum cutting

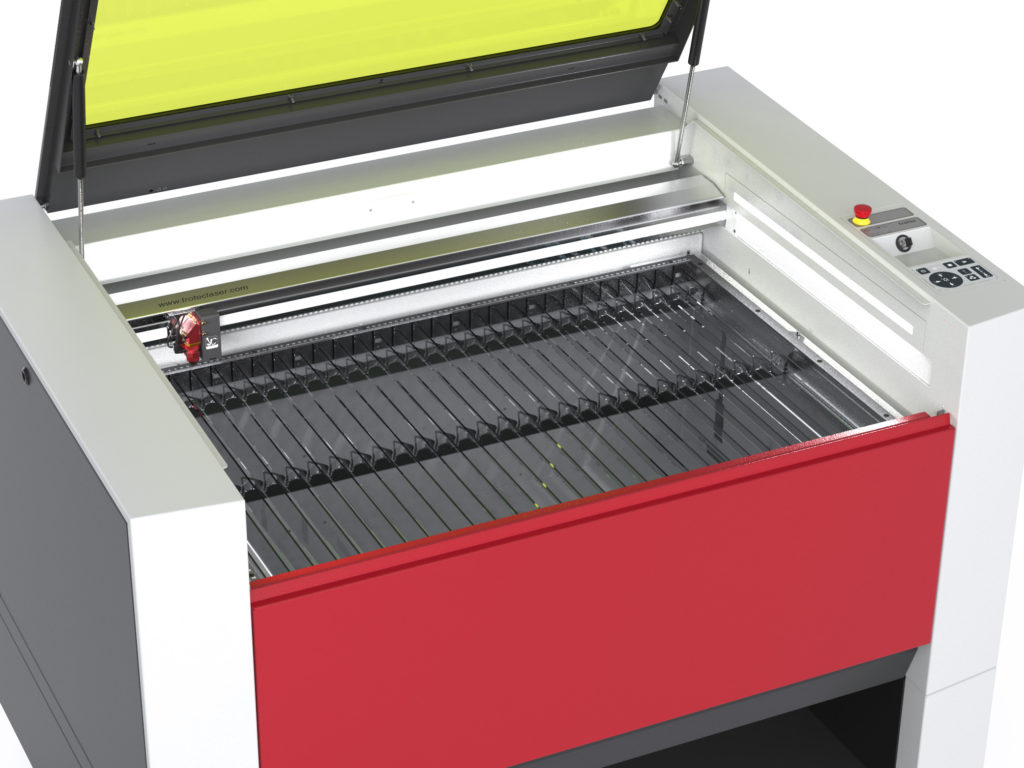

The cutting table with aluminum slats is mainly used for cutting thicker materials (from 8mm thick) and for parts wider

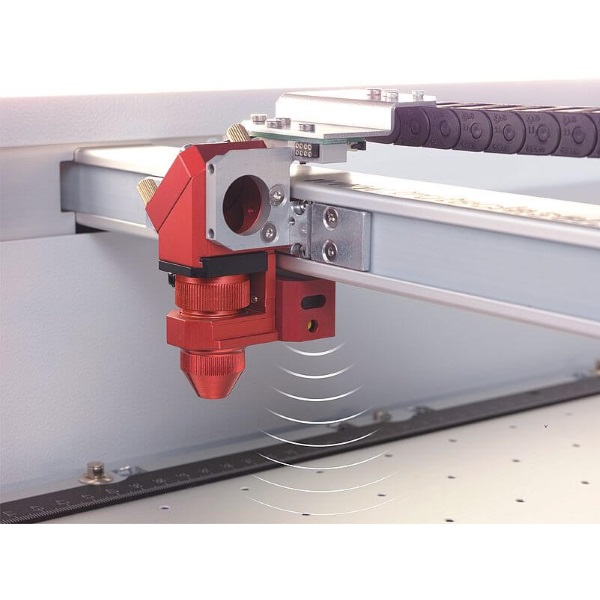

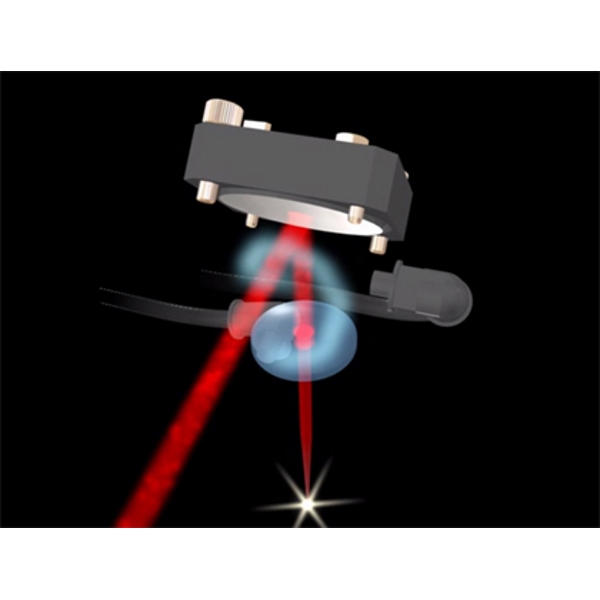

Sonar Technology provides a high level of accuracy when focusing on the material being laser processed, guaranteeing a higher quality.

Light barriers for optimal adjustment of working height and focusing.

With the Software Autofocus, the laser beam is focused for laser engraving, laser marking and laser cutting with just one press of the button.

The trolley table converts your Speedy into a standing unit. Also available with storage shelf for essential materials.

Ensures higher productivity and lower running costs thanks to minimum maintenance and optimal protection against dust.

Provides optimum protection against dust penetration as it seals the engraving compartment.

Full flexibility in the application Using the pass-through, it is possible to engrave or cut very long and bulky parts

Ergonomic access The Speedy 400 works entirely without any front struts, which ensures easy and ergonomic access to the engraving

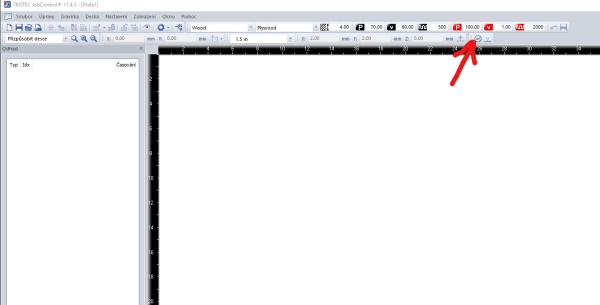

Control software for even the most demanding industrial applications.

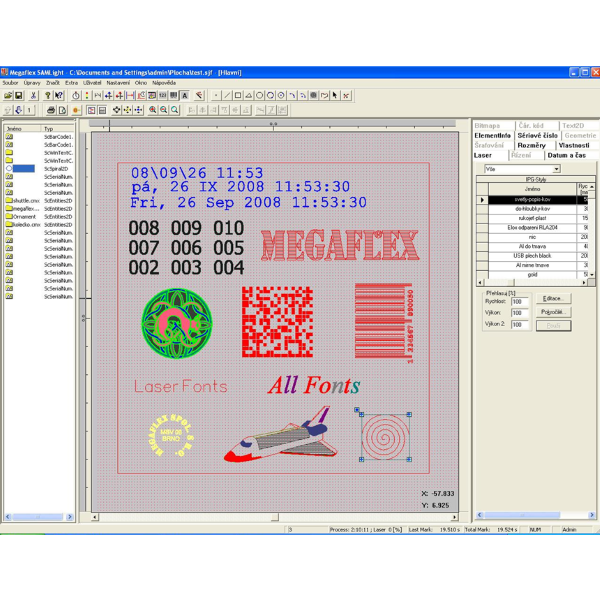

A single software for all work steps The SpeedMark laser software was specially developed for Trotec galvo marking lasers. It

The camera based SpeedMark Vision – Smart Adjust provides highest usability and precision for positioning of marking contents directly on

Using UMark software, you can create content directly in your software and import it. Visual programming with a graphical user

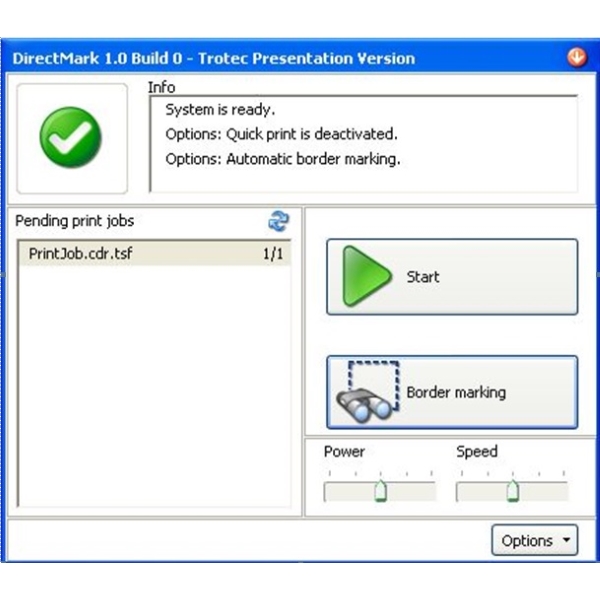

Laser marking – as easy as printing With the DirectMark printer driver, your marking laser is as easy to use

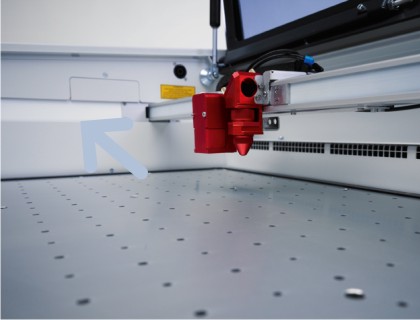

Access to the laser work surface from all 4 sides

Ergonomic and practical control panel supports work with SP lasers The ergonomic and practical control panel supports work with SP2000

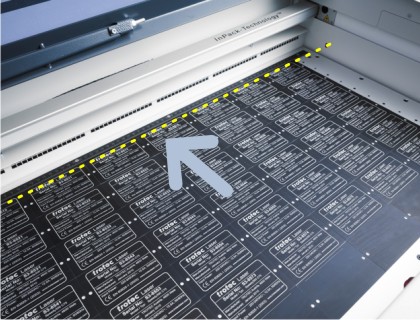

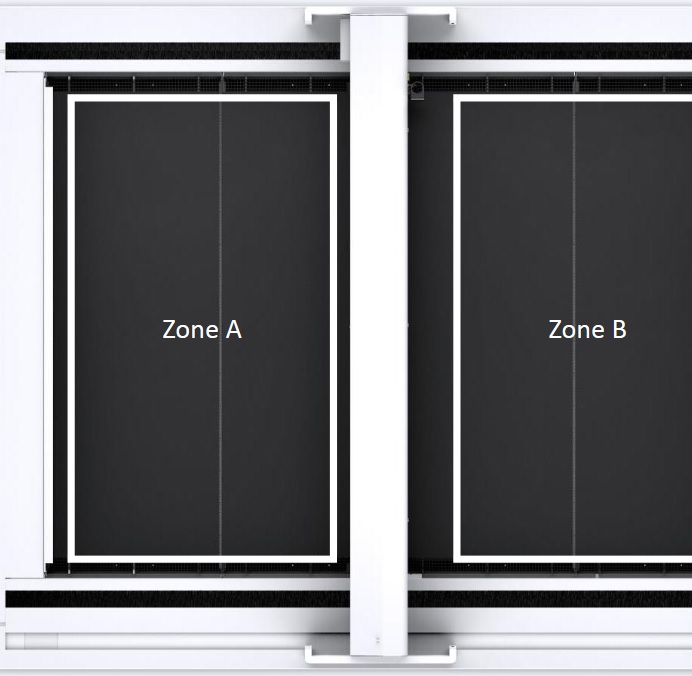

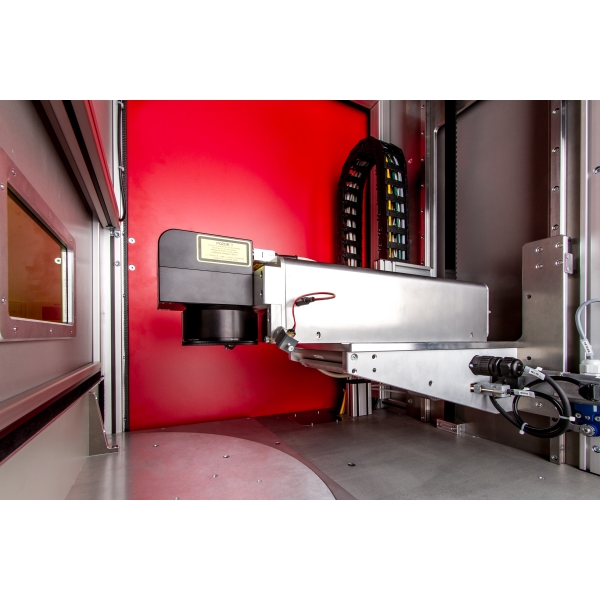

Non-stop laser cutting with Tandem Assist The tandem arrangement provides the operator with efficient and flawless support at work. With

The water cooler prevents the laser performance from fluctuating in difficult climatic conditions.

Efficient extraction An exhaust that is directly attached to the laser head removes dust and gases generated during the laser

Dust-free optics at all times All optics are air-flushed. Compressed air is supplied to the corresponding lens or mirror. Dust

For perfect cutting results: Gas-Kit Using the Gas-Kit, up to 2 process gases can optionally be connected (e. g. compressed air,

Monitors the temperature in the engraving compartment and thus reduces the flame risk during laser cutting.

Safe laser machine enclosure Thanks to the unique design of the enclosure, the SP1500 machine fulfills laser safety class 2.

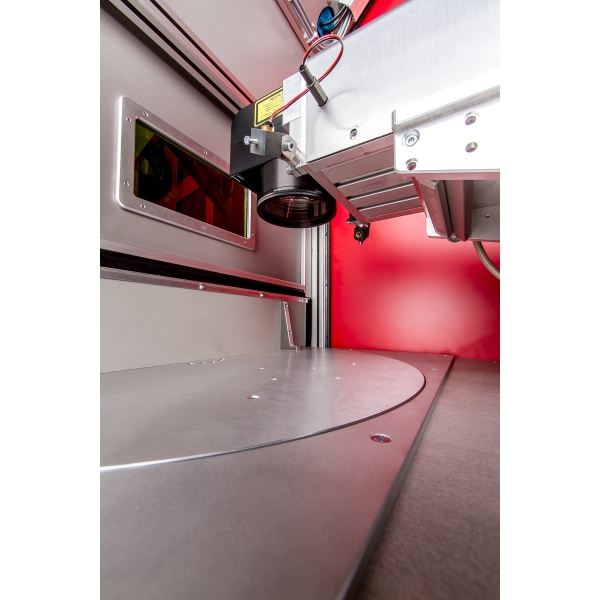

The Z axis is intended for refocusing the laser head. It allows you to find the optimal focus for marking

The modular design of the servant station is equipped as standard with a manual Z-axis drive. Option – Upgrade from

The modular design of the Servant station, which is equipped with a manual Z-axis drive as standard, can also be

The modular design of the Servant station, which is, among other things, equipped as standard with a manual Z-axis drive,

The LED backlight allows you to better position the marked object in the cabin space under the laser head. The

To increase work efficiency, among other optional accessories, there is also an automatic measurement of the height of the object

The Servant station is equipped as standard with a lifting front window with a counterweight, where opening and closing is

Do not hesitate to contact us, our professional staff will be happy to advise you on anything about lasers.

You may use our smart filter in the catalog, too.

Mgr. Jiří Dušek

Head of the Laser department

website by dreamspace.cz