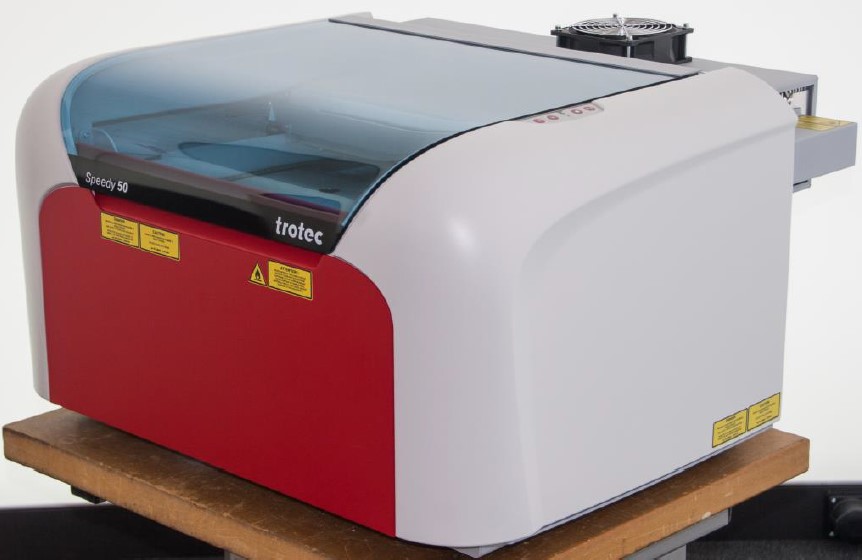

Trotec Production und Vertriebs, GmbH

The Austrian company Trotec was established in 1997 from the development and research department of the parent company, Trodat, which is the world leader in the production of self-inking stamps. In 2012, it already celebrated the 100th anniversary of its successful existence.

Over the years, Trotec has grown organically and today it is certainly the innovative leader of the world’s surface laser market – of course also thanks to the Trodat Group’s extensive global business network and its stability.

The entire group today generates a turnover of over 154 million euros and employs around 1,150 people worldwide in 30 branches. In many other countries, Trotec is represented by a separate company, such as Megaflex on the Czech and Slovak markets. Trotec exports more than 98% of its production.